Leak Test Procedure for Piping

Notify the clientconsultant and get the test witnessed by the consulting engineer. ASME-B315 Refrigeration Piping Test Plan Template Reference.

How To Conduct A Hydrostatic Test On Ductile Iron Pipe Youtube

Tap image for more info on this tool.

. New York a lost American silent comedy drama by George Fitzmaurice. New York a Bollywood film by Kabir Khan. Pressure Test Data Sheet Example WI-400-260-FM04 R4 Reference.

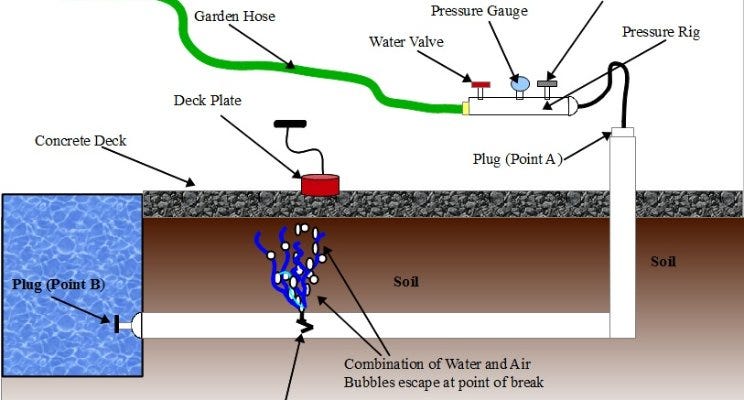

Pressure tests are a non-destructive way to guarantee the integrity of equipment such as pressure vessels pipelines plumbing lines gas cylinders boilers and fuel tanks. All restrained gasketed joints shall be tested in accordance with ASTM D4161. The test crew must attend a toolbox talk Wearing PPE must be made mandatory for all personnel invo9lved in testing.

A short summary of this paper. Wall thickness is acceptable. When a system leak test at a pressure greater than the minimum test pressure specified in c or greater than 150 of the design pressure within the limitations of para.

Our engineers and technicians have industry experience so they know your pain points and can better help you address them. Hydrostatic Test Procedure of Piping JERES-L-105 Piping Material Specifications JERES-L-350 Construction of Plant Piping JERES-L-460 Pipeline Crossings under Roads and Railroads JERES-L-450 Construction - On-Land Near-Shore Pipelines JERES-L-150 Pressure Testing of Plant Piping and Pipelines JERES-A-004 General Requirements for Pressure Testing JERES-H-001 Coating. It is important to keep the micron gauge mounted above the system piping this will prevent system oil from entering the micron gauge and possibly causing the gauge to malfunction.

This Procedure is applicable to Boiler External piping and Pressure vessels constructed to ASME Code B311 sec VII Div 1. An annual precision leak detection test. Hold the piping under pressure for duration of 2 hours and observe for any leakage or pressure drop if the pressure gauge shows a steady reading after 2 hours.

ASME-B315 Specific Leak Testing Data Sheet ADMIN-4-1 Pressure Vessel Inspection and Test Procedure. Well Water Supply Piping Leak Diagnosis Repair - Characteristics of a leak in the pipe between well and building Effects of well piping leaks diagnosis effects remedy A simple guide to the types of leaks that occur in water pipes drain pipes plumbing fixtures Causes of well piping leaks The Old House Repair. Continuous in-tank leak detection.

New York Burgess book a 1976 work of travel and observation by Anthony Burgess. The test speciment shall be considered to have failed in case of a leak weep or rupure. A qualify joints not included in the UT or radiographic examination and b determine the leak tightness of the welded and flanged joints.

Minor repairs and additions are not required to be pressure-tested provided that the work is inspected and connections are tested with a noncorrosive leak-detecting fluid or other leak-detecting methods approved by the Authority Having Jurisdiction. C2-1 LOW-PRESSURE HYDROGEN. If your single-walled underground piping leaks you must immediately withdraw it from service.

Pressure testing also called hydrostatic testing is carried out after the cooling or heating. Food and Personal Care. People also downloaded these free PDFs.

Procedure for Pressure Test or Hydrotest SCOPE. Schedule 10S to Schedule 80S stainless steel pipe is also acceptable for both plain end and threaded. Leak inspection must be performed at least 15 minutes after the test pressure has been reached and this has to be inspected only by designated personnel.

The test pressure will be as per agreed terms and as per Civil Defense requirements. 34521a is required bellows-type expansion joints shall be removed from the piping system or temporary restraints shall be added to limit main anchor loads if necessary. Great care must be taken to minimize the chance of a failure during a.

The manufacturer requires that test operators be certified at least every two years. OD stainless steel tubing 0035-in. New York an American silent drama by Luther Reed.

Learn more about our Testing Services. It also applies to pressure retaining items repair or altered in accordance the National Code NBIC REFERENCES. You must either replace the piping with approved piping or permanently withdraw the system from service.

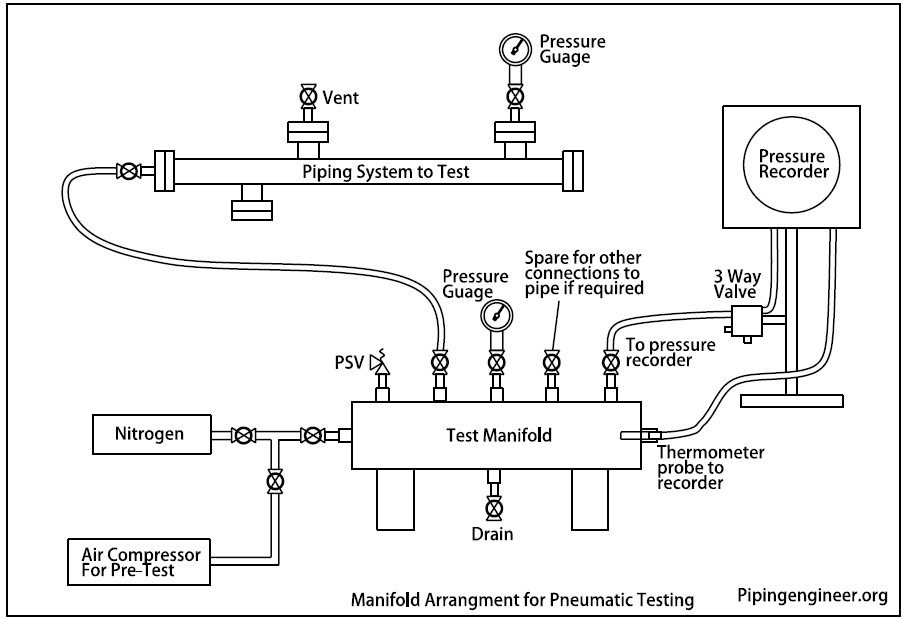

022916 ADMIN-4-2 Hose Assembly Inspection Guidance 0. Piping systems must be designed so that the process pressure of the gas will not exceed the MAWP of the pipe tubing or components. Standard Pneumatic Test - means a leak test of a pressure piping system using air or nitrogen conducted by an organization that holds an Alberta certificate of authorization permit to construct pressure piping using a procedure referenced in their QMS manual and within the stored energy temperature and material limitations established in this document.

Peter Smith in The Fundamentals of Piping Design 2007. This testing includes test of the complete piping system. People also downloaded these PDFs.

The Mesa 2-D test also detects vapor bubbling P-L frequency leak indicating that the oil storage tank or its piping contains a leak in the oil piping or oil filler piping portion of the system. All components shall be tested in accordance with ASTM D1599. PROCESS PIPING DESIGN HANDBOOK - VOLUME 2 Advanced Piping Design Muhammad Nasrullah.

Outlet piping drain piping piping supports and appurtenances Identifying evidence of leakage or inadequate insulation or other coverings An internal inspection is conducted once the pressure has been released and the system is open for inspection. Our industry experience includes. Now you can begin the evacuation process.

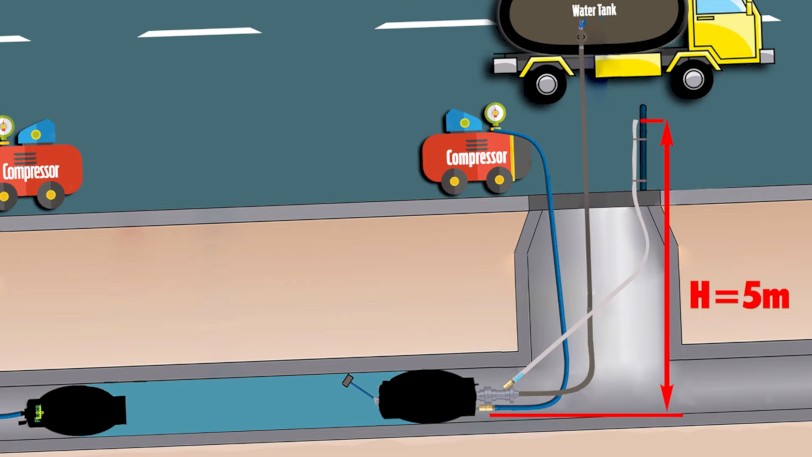

Hydrostatic Leak tests of welded piping systems serve the following purposes. However gas testing involves the hazard of the piping system retaining stored energy that could have a very damaging effect if there is a failure. It is required by the piping codes to confirm that a piping system is able to bear its rated pressure and it has no leaks.

In physics and engineering permeation also called imbuing is the penetration of a permeate a fluid such as a liquid gas or vapor through a solidIt is directly related to the concentration gradient of the permeate a materials intrinsic permeability and the materials mass diffusivityPermeation is modeled by equations such as Ficks laws of diffusion and can be. The fluids most commonly used for a pneumatic test are air or nitrogen. A Documentary Film a film by Ric Burns New York an episode of GleeLiterature.

Where repairs or additions are made following the pressure test the affected piping shall be tested. Litigation and Legal Support. I Edition 2007 Addenda 2009.

Full PDF Package Download Full PDF Package. 742 Pneumatic Leak Test. Continuous external leak monitoring.

Please read the manufacturers vacuum pump start up procedure before starting. This is a low negative pressure or vacuum test using a vacuum of 60 inches of water or 216 psig. 23 Full PDFs related to this paper.

It includes inspecting for corrosion and wear around and defects at Welded seams nozzles and areas adjacent to welds Vessel.

Pneumatic Testing Of Piping Systems The Piping Engineering World

Engineering Guide Pvc Pipe Hydrostatic Pressure Test Post Installation By S Mohammad M Hussaini Medium

No comments for "Leak Test Procedure for Piping"

Post a Comment